Simon Martin

Vice President Consulting Services

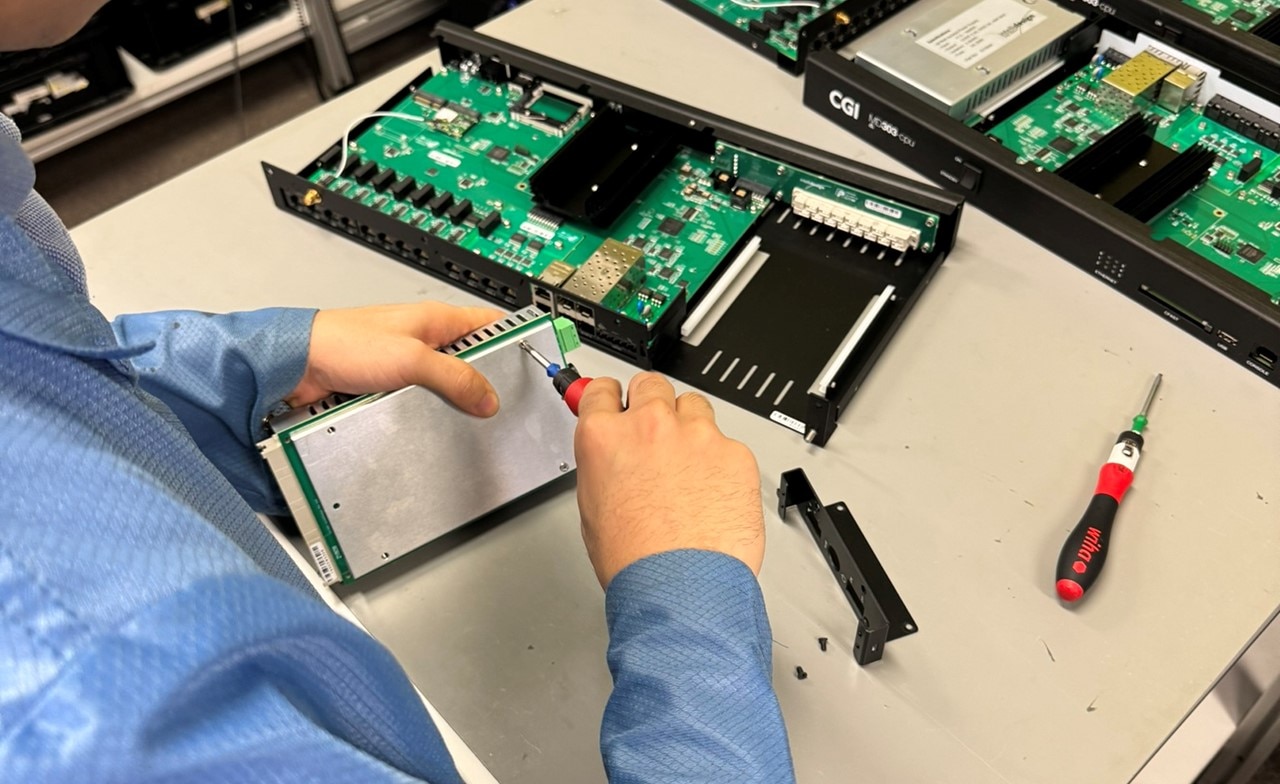

Simon joined CGI in 1998 and leads CGI’s Utilities business in Australia, providing IT, OT and Cybersecurity services that transform, optimise and secure the operations of critical infrastructure providers across the power, gas and water sectors.