Every day, the resilience of supply chains worldwide is tested. Supply chain executives are being asked to orchestrate more resilient, sustainable and customer-centric supply chains. Whether by improving transparency to demonstrate sustainability credentials, building data-driven supply chains to respond to customer expectations faster or navigating intricate supplier landscapes, building sustainable supply chains to support business outcomes is crucial.

Together with Manufacturing Digital, we surveyed 87 supply chain professionals, across manufacturing sectors, to gather their views on navigating the future and the areas they prioritize for success.

Becoming data-driven underpins a resilient supply chain

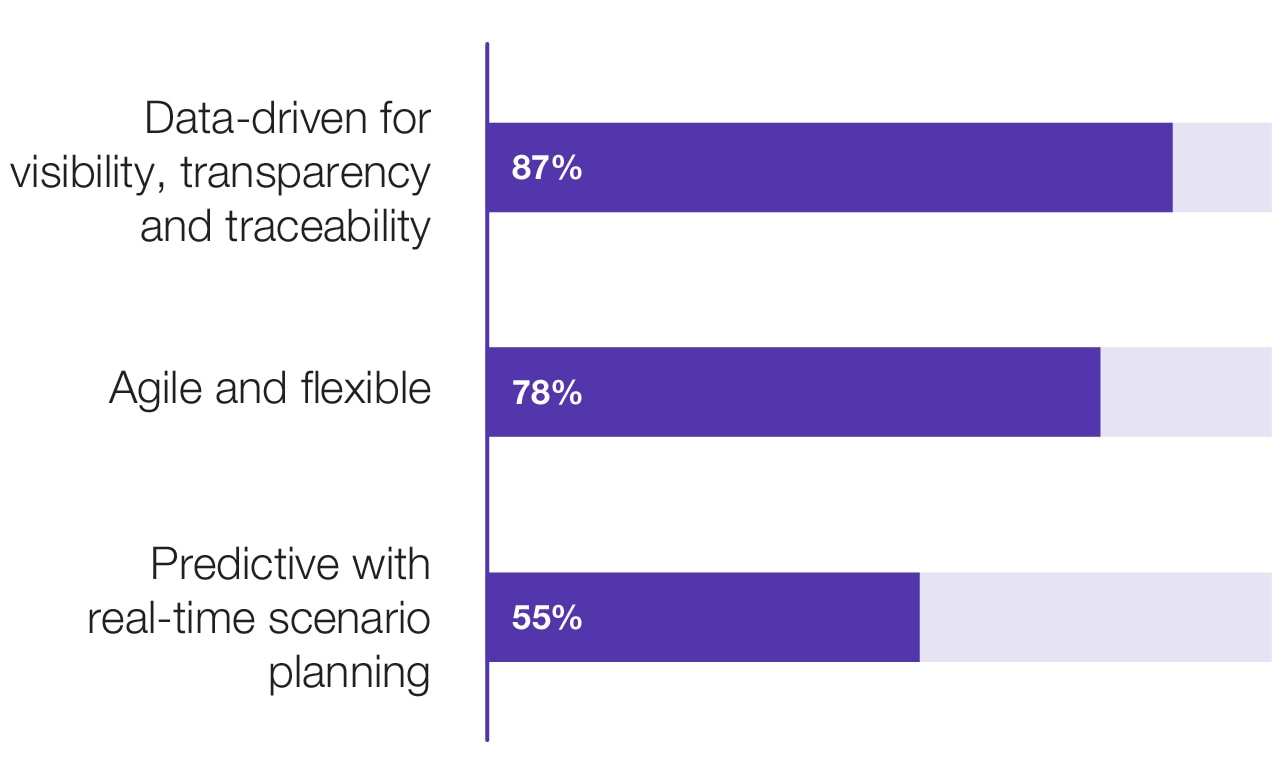

What are the top 3 attributes of a resilient supply chain?*

Supply chain security is table stakes; sustainability requires a stronger focus

How would you rate your supply chain, on a scale of 1-10, with 8-10 being “high,” for the following core attributes of a future supply chain?

|

40%

Data-driven

|

29%

Predictive with real-time scenario planning

|

37%

Local production

|

|

20%

Carbon neutrality and ESG

|

43%

Secure and protected

|

33%

Agile and flexible

|

Percentage of respondents rating their organization “high” (8, 9 or 10)

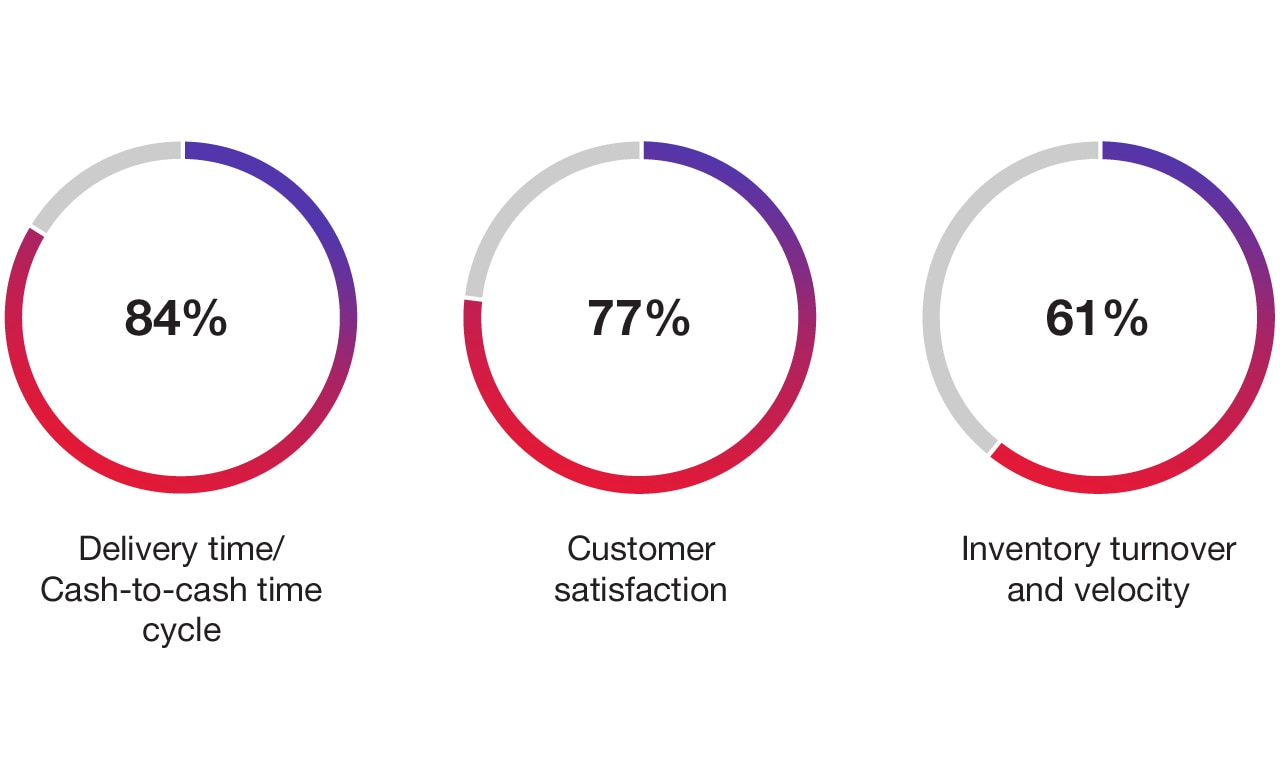

Delivery time/cash-to-cash time cycle emerges as the leading supply chain performance indicator

How would you rate your supply chain, on a scale of 1-10, with 8-10 being “high,” for the following core attributes of a future supply chain?

What are the top 3 KPIs for supply chains?*

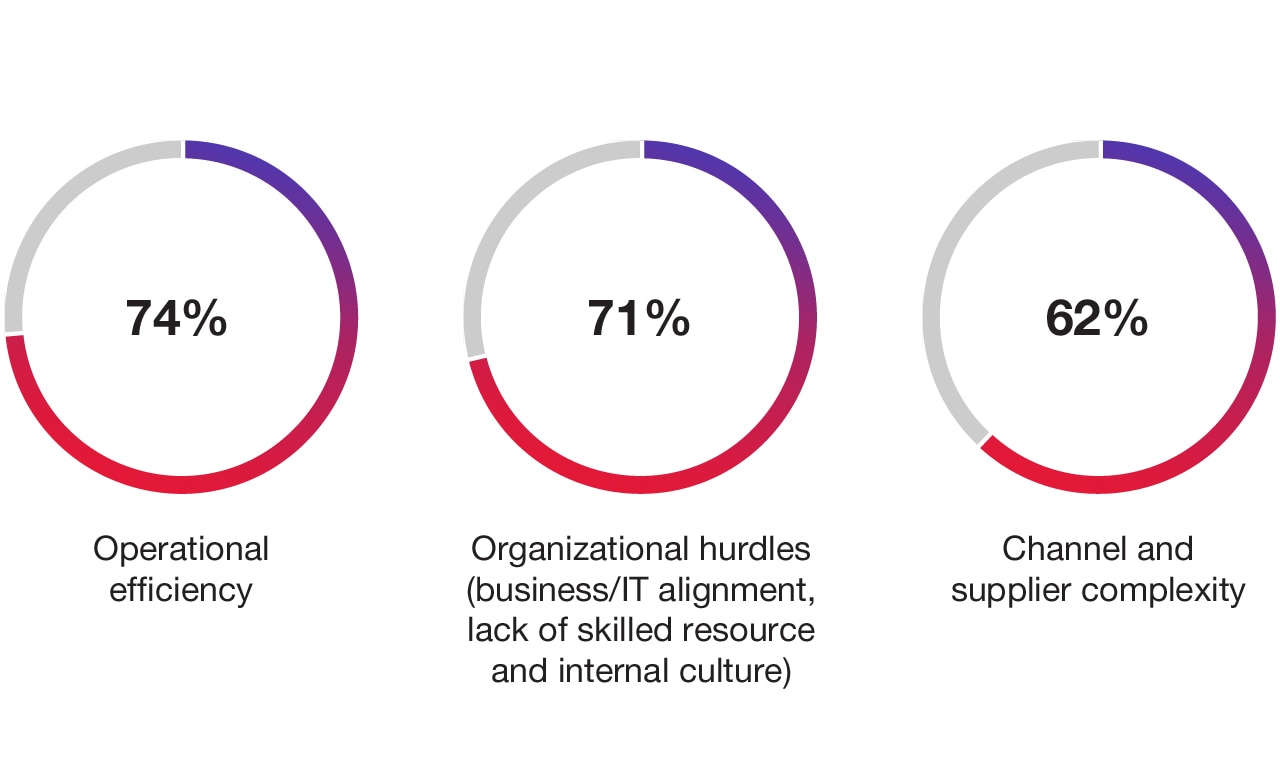

Operational efficiency is the top hurdle to achieving objectives

What are the three biggest challenges in achieving top KPIs and objectives?*

Artificial intelligence and simulation capabilities are the technologies of choice for future initiatives

Which technologies will support supply chain initiatives in the next 1-2 years?*

|

69%

Artificial intelligence (AI), simulation capabilities, advanced analytics, digital twins

(60 responses)

|

66%

Advanced planning system, including integrated business planning

(57 responses)

|

56%

Enterprise resource planning (ERP) and manufacturing cloud

(49 responses)

|

Future supply chains will focus on intelligent scenario planning using AI and simulation capabilities

What are the top three focus areas for the next 5+ years?*

|

69%

Intelligent scenario planning incorporating AI and real-time decision-making

(60 responses)

|

66%

Developing employees’ supply chain know-how and/or attracting talent

(57 responses)

|

56%

Sustainability and reducing carbon emissions

(49 responses)

|

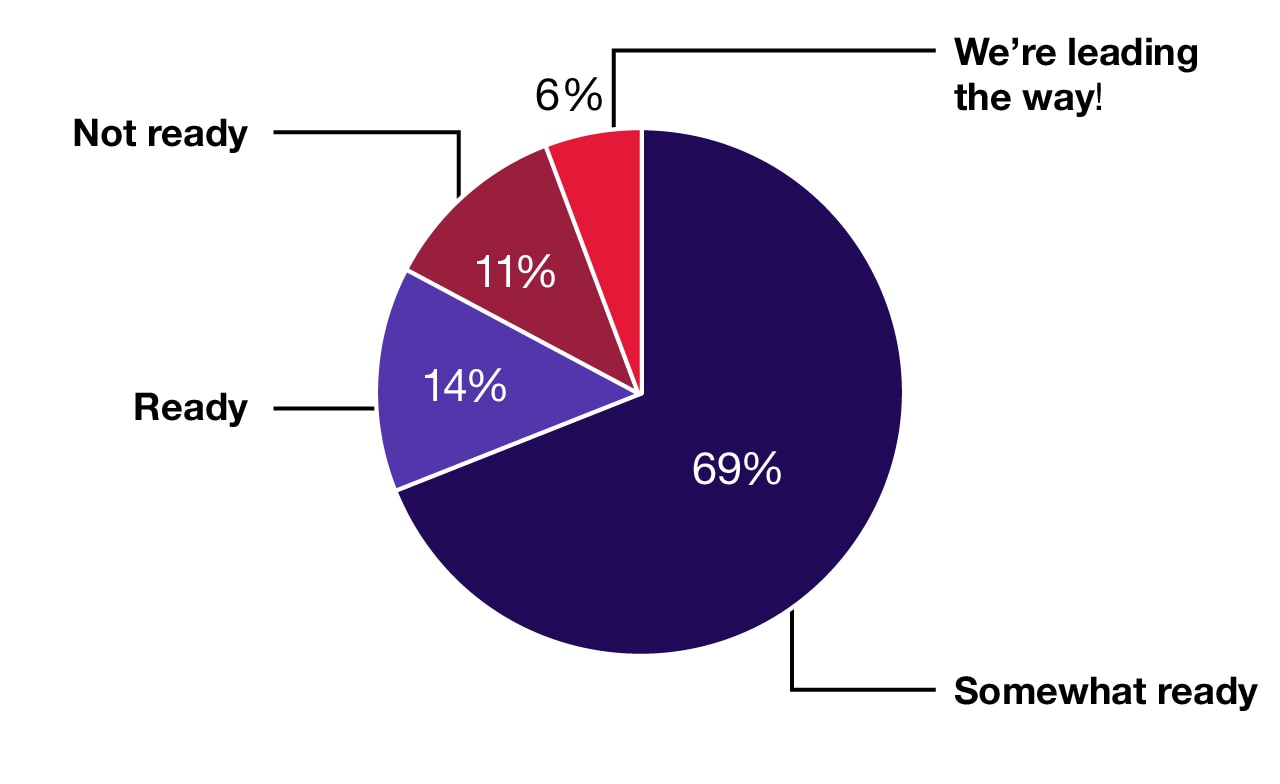

Majority are on the journey toward future readiness; however, only 14% cite readiness

How prepared is your supply chain for the future?

* Respondents were asked to pick their top 3 attributes out of a possible 7.

Key takeaways

Data is fundamental to success

|

1

|

In addition to being able to trace and track, upcoming sustainability regulations demand greater insight into key metrics across the value chain. Data-driven organizations are better positioned to evolve their ecosystems to be more agile and flexible—two key qualities for navigating the extreme pressures of today’s VUCA landscape. This is also a prerequisite for transforming data into actionable insights through predictive analytics and real-time scenario planning. |

Gaps in achieving future readiness must be addressed

|

2

|

While 42% of executives rate their supply chains “high” for the attribute of security, only 19% do so for carbon neutrality/ESG. Given the importance of sustainability for future value creation, it is unsurprising that less than 15% of executives feel their supply chains are ready for the future. |

A holistic view of the entire supply chain is crucial

|

3

|

The top identified supply chain KPIs are cash-to-cash time cycle, customer satisfaction, and inventory turnover. These KPIs are driven by the need to achieve quick turnarounds with high-quality service offerings while reducing capital employed and GES emissions. However, operational efficiency, organizational alignment, channel complexity and integrating GES emissions into critical decision criteria pose challenges to achieving them. With so many moving parts, business units, inputs and outputs, using supply chain digital twins to ensure a connected, holistic view of the supply chain—from raw materials to end users—is paramount. |

Artificial intelligence and digital twins are key enablers of resilience, innovation and growth.

|

4

|

Manufacturers are exploring the responsible use of AI for forecasting, inventory management and implementing data-driven decision-making processes using digital twins with simulation capabilities. AI can help predict potential failures and risks and recommend mitigation action plans. In addition, equipping S&OE processes with a supply chain control tower (a real-time engine with AI and simulation capabilities) is a top focus. Advancing these initiatives, supported by knowledge management systems for supply chain personnel is key to ensuring sustainable performance. Once this level of technological maturity is achieved, manufacturers can begin automating certain supply chain decisions, so that their teams can focus on more high-value decision-making. |