In the dynamic and complex realm of logistics, real-time visibility into processes, assets, and resources is essential. Achieving this visibility can be challenging due to the need to consolidate data from multiple sources and manage large datasets and a multitude of devices.

However, organizations that persevere and ultimately achieve this transparency benefit from actionable knowledge and optimization through the integration of advanced analytics and innovative technologies. When tailored to process-specific needs, this approach provides clarity and enables informed strategic decision-making.

Maximize the potential of your data

While data management can present unique challenges within the complicated logistics realm, there are specific processes and actions that can help unlock the full value of data. In particular, consider these three:

Dashboards for visibility and observability: Dashboards play a pivotal role in the presentation of key metrics, offering a clear and concise view of logistics performance, in real-time. These dashboards provide every stakeholder, from ground-level operators to top-tier management, with the information they need to drive success.

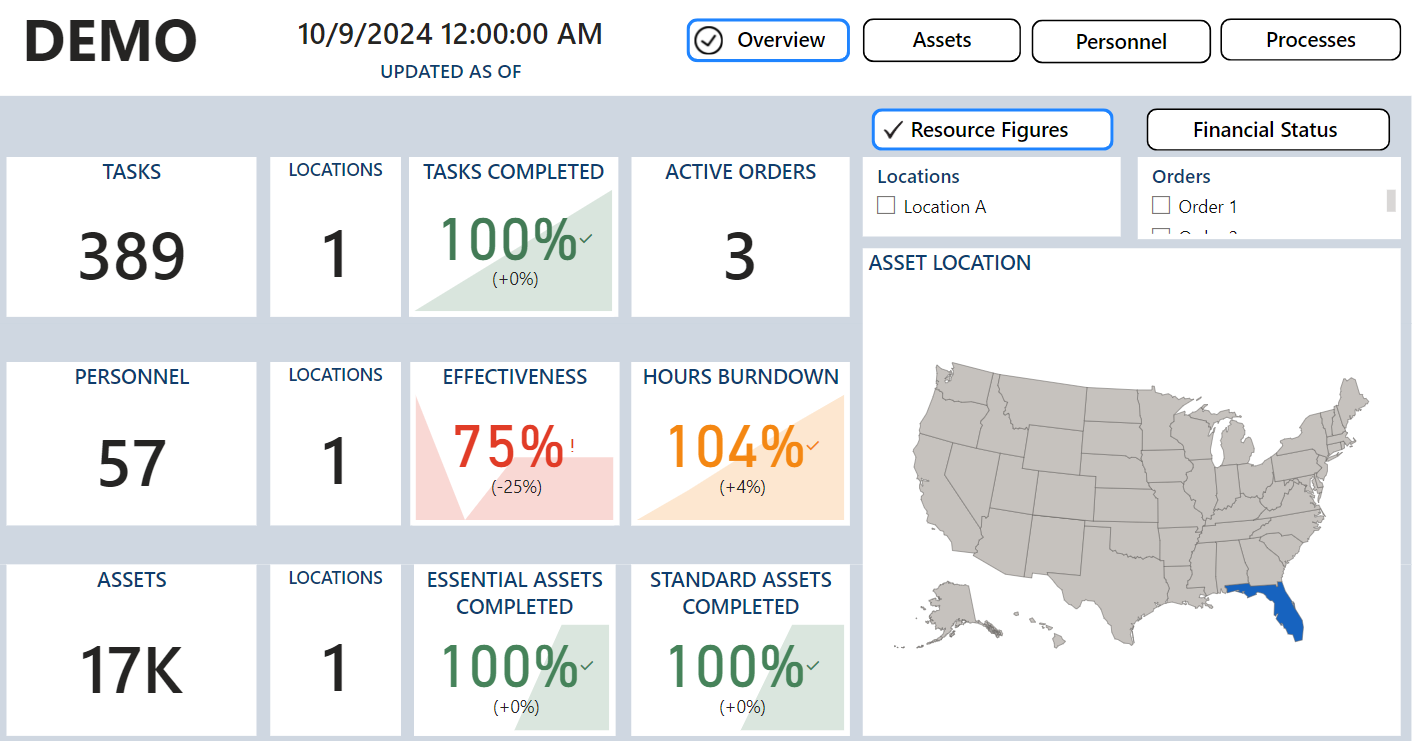

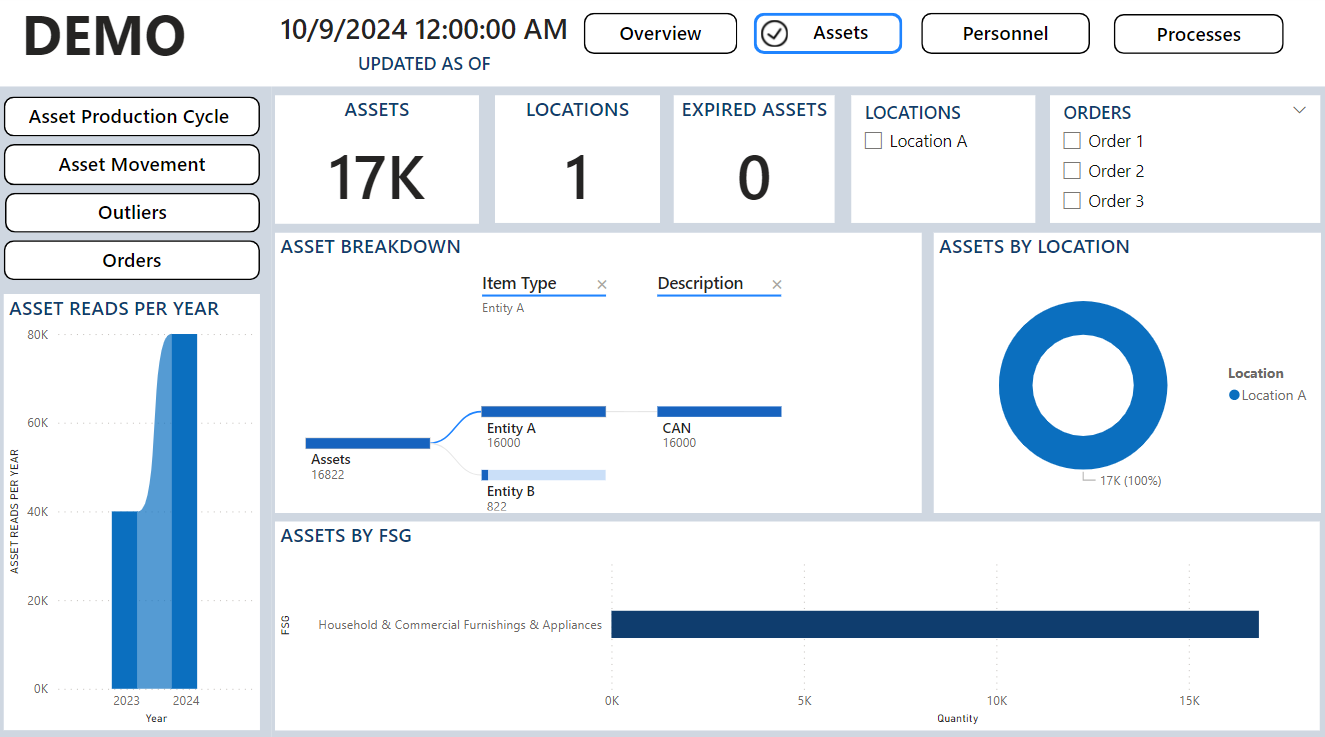

Take a look at figures 1 and 2 below. They represent a simplistic example of a resource overview dashboard and an asset overview, respectively. From these examples you can see how helpful it is to have this data collected onto a single screen.

Implementation of well-designed dashboards and reports enables precise tracking and management of process progression, reducing waste and ensuring that critical resources are always available when needed.

Figure 1. Overview of available resources and production progress.

Figure 2. General asset overview.

Integrating advanced tracking technologies, such as Internet of Things sensor data, into these dashboards enables real-time monitoring of asset locations and statuses. This real-time integration improves the ability to predict and address potential disruptions, ensuring a smoother flow of assets through the supply chain. Furthermore, leveraging data analytics within these dashboards can reveal patterns and insights, driving continuous improvements and providing strategic foresight.

Implement automations to streamline processes and minimize errors. Historically, repetitive manual processes have been susceptible to human error. Robotic process automation (RPA) can significantly reduce the time and effort required for routine tasks, allowing employees to focus on more strategic activities. Enhancing interoperability with data sources ensures quality data for automated processes and sharing, and standardization in automated reporting analyses. These aspects shift supporting personnel from manual data entry and extraction to data interpretation, empowering them to make informed decisions and effectively meet the demands of their roles.

Integrating machine learning (ML) algorithms can also help in identifying and correcting anomalies in real-time, further minimizing errors. By adopting cloud-based solutions, organizations can ensure seamless data access and collaboration across different departments and locations, enhancing overall efficiency. Additionally, continuous training and development programs for staff can ensure they are well-versed in using these advanced tools, fostering a culture of innovation and continuous improvement.

Leverage AI to prepare for future unknowns. The integration of AI via ML and natural language processing (NLP) further reimagines logistics management. By interacting with your data, hidden patterns and insights can be uncovered. Predictive analytics and forecasting enable stakeholders to model various "what-if" scenarios, providing valuable insights into potential future events based on historical data. By leveraging these tools, decisionmakers can anticipate challenges, optimize strategies, and ensure readiness for any eventuality, thereby enhancing resilience and strategic planning. By embracing automation and AI, logistics operations can further streamline processes, reduce manual errors and enhance overall efficiency.

Contested logistics

In contested logistics scenarios, where supply chains may be disrupted by external factors, having a comprehensive and adaptable strategy is crucial. Advanced data analytics and AI-driven insights can help predict potential disruptions and inform contingency plans, ensuring that logistics operations remain resilient and responsive. For maintenance implications, understanding the financial impact of maintenance decisions allows for more strategic planning and resource allocation. By knowing the financial costs, organizations can make informed decisions that increase efficiency and reduce unexpected expenses.

Moreover, the integration of predictive maintenance can further optimize resource allocation by anticipating equipment failures before they occur, thereby reducing downtime and maintenance costs. Again, by utilizing IoT sensors and real-time monitoring, systems can provide continuous updates on asset conditions, enabling proactive maintenance and extending the lifespan of critical infrastructure.

The integration of advanced technologies for logistics management offers significant benefits in terms of resource control, visibility, and informed planning. By leveraging real-time data access, AI-driven insights, and customizable dashboards, logistics operations can achieve greater efficiency, resilience, and adaptability. Furthermore, cloud-based solutions facilitate seamless data sharing and collaboration across different departments and geographical locations, enhancing overall operational efficiency. This comprehensive approach ensures that all levels of the organization are equipped with the information they need to succeed in a competitive and evolving environment.

How CGI can help

We empower our client-partners with real-time insights into their processes, inventory and resource control and allocation. Learn more about how we can help you tackle your logistics challenges.